What Is Inbound Logistics & Outbound Logistics? A 2025 Guide

In the dynamic world of supply chain management, understanding the nuances of inbound and outbound logistics is crucial for operational

In today’s global economy, an efficient and well-managed shipping supply chain is essential for businesses looking to stay competitive. With increasing complexities in international trade, businesses must adopt best practices to ensure timely deliveries, reduce costs, and maintain high compliance standards.

Optimizing the shipping supply chain can significantly boost operational efficiency, from seamless coordination between suppliers, manufacturers, and logistics providers to leveraging technology for real-time tracking and enhanced visibility.

One crucial aspect of shipping compliance is ensuring that all necessary customs documentation is filed accurately and on time. Artemus provides an industry-leading solution for ISF (Import Security Filing), AMS (Automated Manifest System), and AES (Automated Export System) filings, helping businesses streamline their customs compliance processes.

Table Of Contents

Shipping supply chains form the backbone of global trade, ensuring goods reach their destinations efficiently and on time. However, this complex network faces numerous challenges that can disrupt operations, increase costs, and impact customer satisfaction.

Below are the key challenges that supply chain professionals in the shipping industry encounter:

Ports worldwide often face congestion due to increasing trade volumes, limited infrastructure, and inefficient operations. Delays in loading, unloading, and customs clearance can lead to cascading disruptions throughout the supply chain. Addressing port inefficiencies and improving turnaround times is critical for maintaining smooth shipping operations.

The shipping industry is highly susceptible to fluctuating fuel prices, which significantly affect operational costs. Additionally, increasing costs for labor, equipment, and compliance with regulations place further strain on shipping companies. Balancing cost-efficiency while maintaining service quality remains a pressing challenge.

Shipping involves navigating a maze of international laws, tariffs, and customs requirements. Frequent changes in trade policies, sanctions, and environmental regulations (such as IMO 2020) add complexity and demand constant vigilance. Non-compliance can result in heavy fines, shipment delays, or even bans.

Natural disasters, geopolitical conflicts, and pandemics can severely disrupt shipping supply chains. Events like port closures, strikes, or changes in trade routes create bottlenecks that ripple across global supply chains. Building resilient systems to withstand these disruptions is essential.

The absence of real-time tracking and transparency makes it difficult to monitor shipments, leading to inefficiencies and delays. Customers increasingly demand real-time updates, and the lack of visibility can damage trust and impact business relationships.

A mismatch between supply and demand often results in capacity shortages, especially during peak seasons. Limited availability of shipping containers, vessels, and trucking capacity compounds the problem, leading to delays and higher shipping costs.

With growing awareness of environmental impact, shipping companies are under pressure to reduce emissions and adopt sustainable practices. Transitioning to low-sulfur fuels, implementing energy-efficient technologies, and complying with environmental regulations require significant investment.

Despite advancements, many shipping companies still rely on outdated systems, leading to inefficiencies. Integrating modern technologies like IoT, blockchain, and AI into legacy systems remains a challenge for smaller players with limited budgets.

Related: Full Container Load Meaning (FCL) & Key Considerations

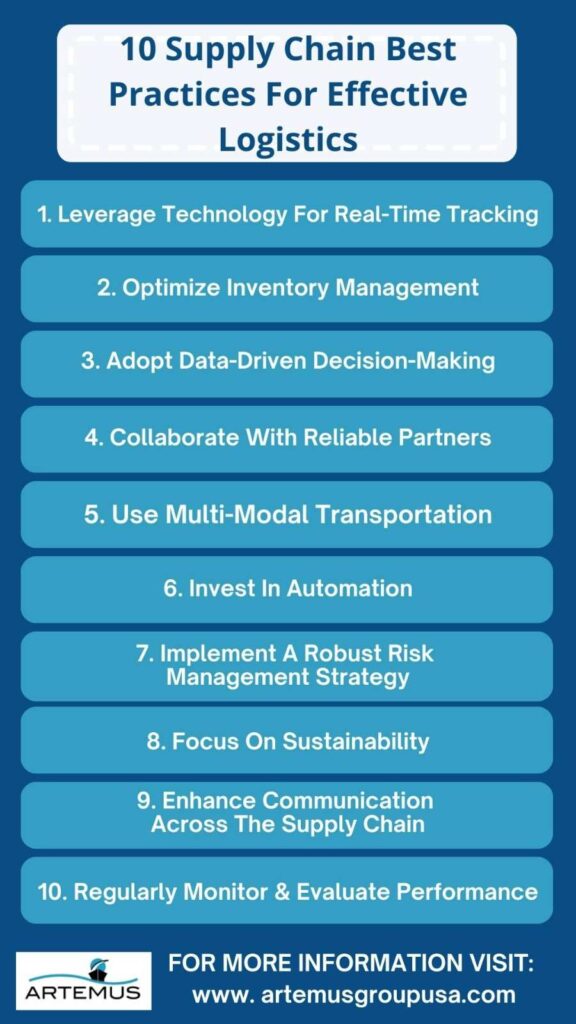

Efficient logistics is the cornerstone of a well-managed supply chain, ensuring the timely delivery of goods while minimizing costs and maximizing customer satisfaction. Here are ten best practices that can help businesses enhance their logistics operations:

Implement advanced technologies such as IoT and GPS to gain real-time visibility into shipments. Tracking tools enable better decision-making, reduce delays, and enhance transparency throughout the supply chain.

Balance inventory levels to avoid overstocking or stockouts. Use inventory management systems (IMS) to analyze demand patterns, forecast trends, and maintain optimal stock levels, ensuring smooth operations.

Leverage big data and analytics to gain actionable insights. By analyzing supply chain performance metrics, businesses can identify bottlenecks, improve processes, and anticipate challenges before they occur.

Work closely with trusted suppliers, freight forwarders, and logistics providers. Building strong relationships ensures better communication, efficiency, and reliability in handling goods.

Diversify your shipping methods by combining modes like rail, ocean, air, and trucking. Multi-modal transportation increases flexibility, reduces costs, and ensures timely deliveries, especially in complex supply chains.

Automate repetitive tasks like order processing, documentation, and warehouse operations. Automation reduces errors, increases efficiency, and frees up human resources for strategic activities.

Prepare for disruptions such as natural disasters, geopolitical issues, and equipment breakdowns. Develop contingency plans, diversify suppliers, and ensure proper insurance coverage to mitigate risks.

Adopt eco-friendly practices, such as using energy-efficient transportation, reducing packaging waste, and optimizing routes to lower carbon emissions. Sustainability initiatives can reduce costs and align with consumer expectations.

Seamless communication among stakeholders ensures smooth operations. Use collaborative platforms to share information, coordinate schedules, and resolve issues promptly.

Conduct regular audits and performance reviews of your logistics operations. Use Key Performance Indicators (KPIs) like on-time delivery rates, shipping accuracy, and transportation costs to assess and improve efficiency.

Related: Merchandise Processing Fee (MPF): A Complete Guide

Freight management is a critical component of supply chain operations, encompassing the planning, execution, and optimization of transporting goods. With growing complexity in global trade, businesses must adopt effective strategies to minimize costs, improve efficiency, and ensure timely delivery.

Here are some key freight management strategies to consider:

Selecting the appropriate transportation mode—air, sea, rail, or trucking—depends on the shipment’s urgency, size, and cost constraints. For instance, air freight is ideal for time-sensitive goods, while ocean freight is cost-effective for bulk shipments.

Efficient route planning reduces transit times, fuel consumption, and overall costs. Use advanced route optimization tools to identify the shortest and safest paths, considering factors like weather, traffic, and geopolitical risks.

Consolidating smaller shipments into larger loads reduces transportation costs and maximizes carrier capacity. Businesses can achieve this by collaborating with third-party logistics (3PL) providers or freight forwarders.

Invest in freight management software to streamline operations, track shipments, and automate tasks like documentation and invoicing. These tools provide real-time insights, improve decision-making, and enhance operational efficiency.

Build strong relationships with carriers to negotiate favorable rates and service terms. Establish long-term contracts to lock in consistent pricing, especially during peak seasons or periods of market volatility.

Leverage GPS and IoT technology for real-time shipment tracking. Visibility into freight movements helps identify delays, improve customer communication, and mitigate risks like theft or loss.

Adopt eco-friendly freight practices, such as using fuel-efficient vehicles, optimizing load capacity, and choosing green logistics partners. Sustainability efforts can reduce environmental impact and meet consumer demands for responsible operations.

Combine multiple transportation modes to optimize cost, speed, and reliability. For example, integrate rail and trucking to balance affordability with flexibility in delivery timelines.

Prepare for potential disruptions by identifying alternative carriers, routes, and suppliers. Contingency plans help minimize the impact of delays caused by natural disasters, labor strikes, or geopolitical events.

Conduct periodic reviews of freight management processes to identify inefficiencies and areas for improvement. Use metrics like on-time delivery rates, freight cost per unit, and transit times to evaluate performance.

Related: Understanding Roll-On/Roll-Off Ships: A Complete Guide

A sustainable supply chain integrates environmentally and socially responsible practices throughout the entire supply chain lifecycle—from sourcing raw materials to delivering finished goods. It focuses on minimizing environmental impact, promoting ethical labor practices, and ensuring economic viability.

A sustainable supply chain aligns with global efforts to combat climate change, reduce resource depletion, and foster community well-being while enhancing business resilience and reputation.

Related: Customs Clearance Delays In 2024: Top 10 Reasons & Solutions

Shipping supply chains are vital for global trade but are vulnerable to various risks, ranging from natural disasters to cybersecurity threats. Effective risk management in shipping supply chains is essential to ensure smooth operations, minimize disruptions, and protect financial and reputational interests.

Related: What Is Harbor Maintenance Fee (HMF)? A 2024 Guide

The shipping industry is undergoing rapid transformation, driven by technological advancements, environmental concerns, and evolving consumer expectations. Future trends in shipping supply chain management aim to improve efficiency, sustainability, and resilience while adapting to the demands of a globalized and digitized economy.

Related: What Happens After Custom Clearance Completed? 9 Next Steps

Artemus offers industry-leading solutions for Import Security Filing (ISF), Automated Manifest System (AMS), and Automated Export System (AES) filings, ensuring seamless customs compliance for international shipments. Our robust software simplifies complex regulatory processes, helping businesses stay compliant with U.S. Customs and Border Protection (CBP) requirements.

Whether it’s reducing the risk of penalties with accurate ISF filings, enhancing cargo visibility through AMS, or streamlining export declarations with AES, Artemus delivers efficiency and precision tailored to your needs.

With a user-friendly interface, real-time updates, and exceptional customer support, Artemus empowers freight forwarders, customs brokers, and logistics providers to navigate the complexities of global trade confidently. Our solutions are designed to enhance supply chain efficiency, reduce operational risks, and ensure timely clearance, making Artemus your trusted partner for comprehensive customs compliance.

Related: NVOCC Bond & OTI Bonds – Federal Maritime Commission

A supply chain encompasses all activities, resources, and entities involved in producing and delivering a product or service from raw material suppliers to the end customer.

Examples of supply chains include raw material procurement for automobile manufacturing, logistics networks for e-commerce companies, or the sourcing and delivery of fresh produce to grocery stores.

Supply chain management practices refer to strategies and processes used to optimize the flow of goods, services, information, and finances across the supply chain, ensuring efficiency and customer satisfaction.

A supply chain strategy aligns with business goals to streamline operations, while supply chain practices are the actions and processes implemented to achieve these strategic objectives.

Best practices in supply chain management include leveraging technology for visibility, collaborating with stakeholders, implementing sustainable practices, and adopting agile methods to adapt to disruptions.

The 7 C’s of supply chain management are Customer Centricity, Collaboration, Cost Management, Connectivity, Commitment, Consistency, and Continuous Improvement.

The 5 W’s refer to Who (stakeholders), What (goods/services), When (timelines), Where (locations), and Why (business goals) in the context of managing a supply chain.

SCM practice involves implementing techniques and technologies that enhance the efficiency, sustainability, and resilience of supply chain operations.

You can improve your supply chain by optimizing processes, embracing digital tools, diversifying suppliers, focusing on sustainability, and building strong collaborations with stakeholders.

Key trends include digitalization, real-time tracking, sustainability, AI and automation, blockchain integration, and last-mile delivery innovations.

The supply chain supports business strategy by ensuring timely delivery, reducing costs, improving quality, and enhancing customer satisfaction, all of which drive competitive advantage and profitability.

Related: Ocean Freight Documentation For Imports: A Crucial Checklist

In the fast-paced world of global trade, adopting supply chain best practices in shipping is no longer optional—it’s a necessity. From optimizing inventory management to implementing advanced technologies for real-time tracking and sustainability, businesses can greatly enhance their efficiency, reduce costs, and improve customer satisfaction.

Related: Less Than Container Load (LCL) Shipping: 2024 Guide

In the dynamic world of supply chain management, understanding the nuances of inbound and outbound logistics is crucial for operational

In today’s interconnected world, businesses rely heavily on global trade to expand their markets, access new resources, and drive growth.

Importing goods for resale in the USA presents a lucrative business opportunity, but navigating the complexities of U.S. customs regulations,

Get In Touch

Artemus’ Software Solutions for ISF, AMS, Japan AFR, eManifest Canada, & Panama B2B filings.