How To Import Goods For Resale In The USA? A 2025 Guide

Importing goods for resale in the USA presents a lucrative business opportunity, but navigating the complexities of U.S. customs regulations,

Ocean container dimensions are essential for efficient global shipping, ensuring that goods are transported safely and cost-effectively. Understanding container sizes, like 20-foot and 40-foot options, helps businesses optimize space and streamline logistics.

Knowing the internal and external measurements of containers allows businesses to plan shipments more effectively, reducing potential issues during transit. Proper container selection ensures smooth loading and unloading.

For U.S. import and export compliance, Artemus: ISF, AMS, & AES solutions are key. These tools help businesses stay compliant with regulations, avoiding delays and penalties while ensuring efficient shipping.

Table Of Contents

When shipping goods across the globe, it’s essential to understand the dimensions of ocean containers. This knowledge ensures that cargo fits properly and avoids shipping delays or extra costs.

Ocean containers are standardized for global shipping, and the most common sizes are:

Outside: 20 ft (6.058 m) long, 8 ft (2.438 m) wide, 8.5 ft (2.591 m) tall.

Inside: Slightly smaller, with a capacity of around 33 cubic meters.

Use: Small to medium cargo.

Outside: 40 ft (12.192 m) long, 8 ft (2.438 m) wide, 8.5 ft (2.591 m) tall.

Inside: Holds around 67 cubic meters of cargo.

Use: Larger shipments or high-volume goods.

These containers are taller, ideal for larger or taller items.

Adds an extra foot of height, giving about 76 cubic meters of space.

Longer and taller, offering over 85 cubic meters.

Feet and Inches (used in the US) and Meters (used globally) are both common in shipping.

Conversion Basics:

1 foot = 0.3048 meters.

1 inch = 0.0254 meters.

1 cubic meter = 35.315 cubic feet.

Some containers have special designs for unique cargo:

Understanding these container sizes and their measurements helps make the shipping process smoother and more efficient. Choosing the right container ensures that your goods are transported safely and within budget.

Related: Full Container Load Meaning (FCL) & Key Considerations

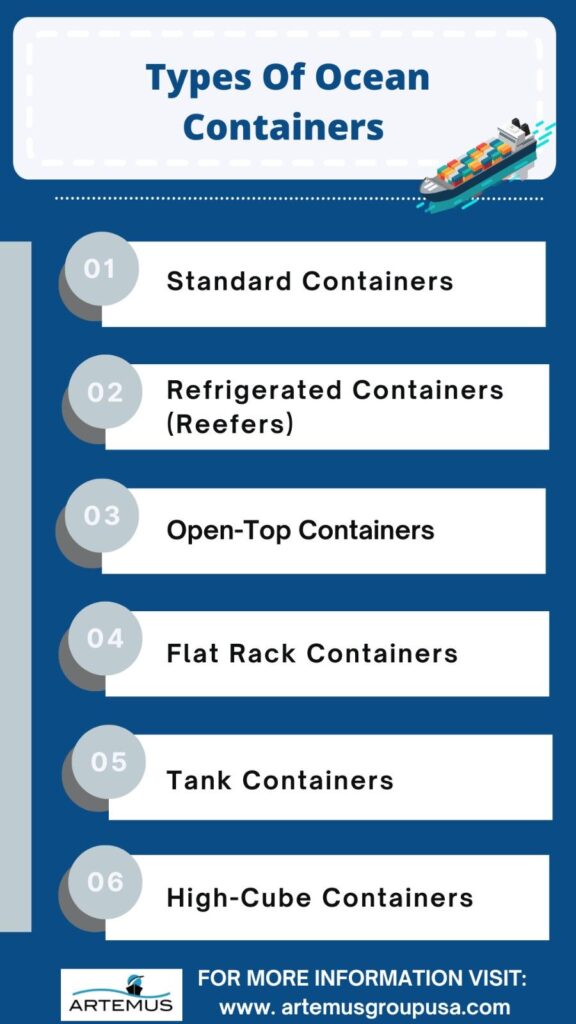

When shipping goods via ocean freight, different types of containers are used depending on the cargo’s needs. Knowing the right container type ensures that your goods are transported safely and efficiently.

These are the most common type of ocean containers used for general cargo.

Reefers are insulated containers with a built-in refrigeration system, designed for temperature-sensitive cargo like food, pharmaceuticals, and chemicals.

Open-top containers have no roof, making them ideal for tall cargo that doesn’t fit into standard containers.

Flat racks are used for transporting oversized or irregularly shaped cargo that can’t fit into standard containers.

Tank containers are designed to carry liquids or gases, ensuring safe transportation of hazardous or non-hazardous materials.

These are similar to standard containers but are taller, offering additional storage space.

Choosing the right container depends on the type of cargo being shipped. Whether it’s temperature-sensitive items, oversized goods, or hazardous materials, understanding the different container types ensures safe and efficient shipping.

Related: Less Than Container Load (LCL) Shipping: 2024 Guide

When shipping goods, understanding the impact of weight and volume capacities is crucial for ensuring efficiency and cost-effectiveness. These two factors determine how much cargo can fit into a container and directly influence shipping costs, routes, and delivery times.

Weight is one of the most important factors in determining shipping costs and container usage.

Volume, or the amount of space a shipment occupies, is just as critical as weight in shipping logistics.

In many cases, both weight and volume play a role in determining the best shipping method.

Selecting the right container involves assessing both the weight and volume of the cargo.

Both weight and volume can also impact the choice of shipping routes and the time it takes to reach the destination.

Understanding the relationship between weight and volume helps businesses plan more efficiently and avoid unnecessary shipping costs. By optimizing container usage, shippers can ensure that cargo arrives safely, on time, and within budget.

Related: 10 Supply Chain Best Practices In Shipping: A 2025 Guide

Choosing the right container for shipping is essential for ensuring that goods are transported safely, efficiently, and cost-effectively. The decision depends on several factors, including the nature of the cargo, container dimensions, and specific shipping needs.

The type of goods being shipped significantly influences the choice of container.

The size of the container plays a critical role in determining how much cargo can be shipped and how efficiently the container is packed.

The weight and volume of the cargo will determine the type of container and the shipping cost.

The shipping route and delivery time are influenced by the type of container and its contents.

The cost of shipping is influenced by the container type and size, as well as the nature of the cargo.

Sustainability is becoming increasingly important in shipping.

Choosing the right container is a crucial part of the shipping process. By considering factors such as cargo type, size, weight, transit time, and budget, you can ensure that goods are shipped in the most efficient and cost-effective manner.

Related: Top 10 Ports In The USA: The Busiest Hubs Driving US Trade

Understanding global standards and regulations for container dimensions is crucial for international shipping.

These standards ensure that containers are compatible with various shipping methods, ports, and transport modes worldwide, promoting efficiency and safety in the global supply chain.

The International Organization For Standardization (ISO) plays a key role in setting the standards for container dimensions.

ISO regulations define standard container sizes, which help in uniformity across global shipping operations.

ISO standards also define the weight and capacity limits for containers to ensure safe and efficient transportation.

Shipping containers must comply with regulations from various international organizations to ensure safety, security, and efficiency.

While global standards are essential, certain regions and countries may have additional requirements for container dimensions.

The future of container dimensions and standards is likely to be influenced by technological advancements and environmental concerns.

Global standards and regulations for container dimensions ensure uniformity, safety, and efficiency in international shipping. By adhering to these regulations, companies can ensure that their goods are transported smoothly, minimizing delays and ensuring compliance with international trade laws.

Related: How To Export Medicine From The USA? A 2025 Guide

Artemus simplifies U.S. import and export compliance by automating key filings like ISF, AMS, and AES. These filings are crucial for ensuring that shipments meet U.S. Customs and Border Protection (CBP) and Census Bureau requirements, reducing the risk of fines and delays.

The Importer Security Filing (ISF) ensures that importers submit essential cargo information to CBP before goods are loaded onto a vessel. Artemus automates this process to ensure timely and accurate reporting, while Automated Manifest System (AMS) filings help with pre-arrival cargo data for better risk assessment.

For exports, Artemus also automates Automated Export System (AES) filings, ensuring that all outbound shipments meet U.S. Census Bureau requirements. This comprehensive solution reduces administrative workload and enhances compliance with U.S. trade regulations.

Ocean containers typically have standard sizes, with the most common being 20 feet and 40 feet. A 20ft container usually measures 6.1m x 2.44m x 2.59m (L x W x H), while a 40ft container measures 12.2m x 2.44m x 2.59m.

A 40ft sea container generally measures 12.2 meters in length, 2.44 meters in width, and 2.59 meters in height, with a total internal volume of approximately 67 cubic meters.

The four common types of ocean containers are:

A typical sea can container (usually a 20ft container) has dimensions of approximately 6.1m x 2.44m x 2.59m (L x W x H), while a 40ft container has dimensions of 12.2m x 2.44m x 2.59m.

A 20ft sea container typically measures 6.1m in length, 2.44m in width, and 2.59m in height, with an internal volume of around 33 cubic meters.

The largest ocean containers are typically 45ft containers, which are slightly longer than the standard 40ft container. Some newer shipping containers can also go up to 53ft in length, mainly used in the U.S.

The price of a 40ft container can vary significantly depending on factors such as condition (new or used), location, and market conditions, but it generally ranges between $2,000 and $5,000.

The number of 40ft containers that can fit on a ship depends on the ship’s size. Large container ships can carry around 10,000 to 20,000 containers, with many of them being 40ft containers.

A 40ft container typically has an internal volume of about 67 cubic meters, which equals approximately 67,000 liters.

Maersk uses standard shipping container sizes, primarily 20ft and 40ft containers, with dimensions similar to the typical ones: 20ft (6.1m x 2.44m x 2.59m) and 40ft (12.2m x 2.44m x 2.59m).

Container sizes are typically labeled on the side of the container, indicating its length, width, and height. Standard sizes include 20ft, 40ft, and 40ft high-cube containers.

It is called a sea container because it is designed for the transportation of goods across seas and oceans, being sturdy and weatherproof for maritime shipping.

In conclusion, knowing ocean container dimensions is crucial for effective shipping. Standardized sizes like 20-foot and 40-foot containers help businesses plan shipments efficiently and avoid space-related issues.

By understanding the internal and external measurements, companies can optimize cargo space and reduce costs. High cube containers offer additional space for specific types of goods.

Ultimately, selecting the right container ensures smooth logistics and cost-effective transportation. Proper planning leads to better efficiency and reliability in shipping.

Related: Export Documentation Requirements To Export From The USA

Importing goods for resale in the USA presents a lucrative business opportunity, but navigating the complexities of U.S. customs regulations,

Cargo agents are the backbone of the global logistics and shipping industries, managing the complex web of tasks that ensure

Ocean container dimensions are essential for efficient global shipping, ensuring that goods are transported safely and cost-effectively. Understanding container sizes,

Get In Touch

Artemus’ Software Solutions for ISF, AMS, Japan AFR, eManifest Canada, & Panama B2B filings.